Power supply coatings cure at high temperatures to form a uniform, dense, and sticky coating. Powder spraying is different from traditional liquid spraying. It has many special good points. That’s why the power of UV resistant coatings is used a lot in industrial production.

How Powder Coating Works

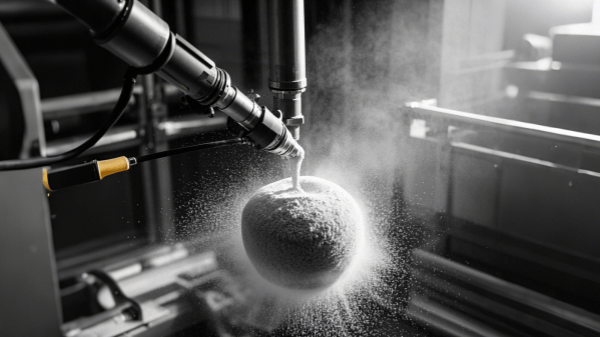

The powder coating process is easy, but it needs high-tech. First, put the powder coating into the spray gun. High-voltage static electricity makes the powder particles charged. Then, spray these charged powder particles onto the grounded workpiece surface. Because of electrostatic attraction, the powder particles stick evenly on the workpiece. Finally, put the workpiece into a high-temperature baking furnace. The powder melts and hardens to make a continuous coating.

Steps of Powder Spraying

Pretreatment: Clean the workpiece by degreasing and rust-removing. This helps the coating stick well.

Spraying: Use electrostatic spraying gear to spray powder coating on the workpiece surface.

Curing: Put the workpiece in the oven. High temperature makes the powder melt, level out, and harden.

Cooling: Let the workpiece cool down to room temperature.

Benefits of Powder Spraying

Powder spraying is better than traditional liquid spraying in these ways:

Environment-friendly: Powder coating has no solvents. It doesn’t make harmful gases when spraying or curing. It’s good for the environment.

High-efficiency: People can use powder coating well. Leftover powder can be used again. This cuts down on waste.

Good coating quality: Powder coating sticks well. It can resist impacts, corrosion, and wear.

Even coating thickness: Electrostatic spraying makes the powder stick evenly on the workpiece surface. The coating is the same thickness all over.

Many colors: Powder coating comes in lots of colors. It can meet different beauty needs.

Nice coating look: The powder-coated surface is smooth and flat. It looks really good.

Conclusion

Powder spraying is an advanced surface treatment. It’s good for the environment, works fast, and looks nice. It’s getting more and more important in industrial production.