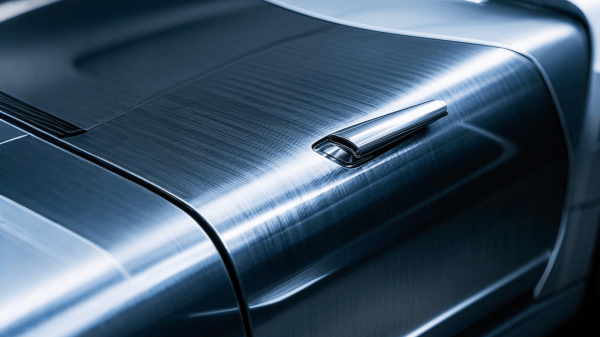

The metal wire drawing technique involves pulling a metal workpiece through a series of dies to reduce its cross-sectional area and achieve a smooth, polished, or textured surface.

Principles of Metal Wire Drawing

Wire drawing is a cold-working process that involves the plastic deformation of metal.The metal is pulled through a die or a series of dies, each with a smaller diameter than the previous one.As the metal passes through the die,it undergoes elongation and reduction in cross-sectional area, resulting in a finer and more uniform surface .The process can be applied to various metals, including steel, aluminum, copper, and titanium.

Methods of Metal Wire Drawing

There are several methods of metal wire drawing,each suited to specific applications and requirements:

Single Draft Drawing: This is the simplest form of wire drawing,where the metal is pulled through a single die.It is commonly used for producing wires with a consistent diameter and smooth surface.

Continuous Drawing: In this method,the metal is passed through multiple dies in succession.Each die reduces the diameter of the wire incrementally,allowing for the production of very fine wires.Continuous drawing is often used in the manufacturing of electrical cables and filaments.

Wet Drawing: This technique involves immersing the metal and dies in a lubricant during the drawing process.Wet drawing is particularly effective for producing high-quality surfaces and is commonly used for stainless steel and other corrosion-resistant alloys.

Dry Drawing: Unlike wet drawing,dry drawing uses a solid lubricant,such as soap or powder,applied to the metal surface.This method is suitable for metals that do not require a high level of surface finish.

Bundle Drawing: In bundle drawing,multiple wires are drawn simultaneously through a single die.This method is efficient for producing large quantities of wires with similar dimensions.

Applications of Metal Wire Drawing

Metal wire drawing is employed in a wide range of industries due to its versatility and ability to produce high-quality surfaces.Some of the key applications include:

Electrical and Electronics: Wire drawing is essential for producing conductive wires used in electrical cables,connectors,and electronic components.Copper and aluminum wires are commonly drawn to achieve the required conductivity and flexibility.

Automotive: In the automotive industry,wire drawing is used to manufacture components such as springs,fasteners,and tire cords.The process enhances the strength and durability of these parts,ensuring they can withstand harsh operating conditions.

Construction: Wire-drawn steel is widely used in construction for reinforcing concrete structures,fencing,and suspension bridges.The process improves the tensile strength and corrosion resistance of the steel,making it suitable for demanding applications.

Consumer Goods: Wire drawing is also used in the production of everyday items such as jewelry,kitchen utensils,and musical instrument strings.The process allows for the creation of fine,intricate designs with a polished or textured finish.

Conclusion

Metal wire drawing is a highly effective surface treatment process that offers numerous benefits,including improved surface finish,enhanced mechanical properties,and dimensional accuracy.Its versatility and cost-effectiveness make it a preferred choice for various industries,from electrical and automotive to construction and consumer goods.As technology continues to advance,the wire drawing process is likely to evolve,offering even greater precision and efficiency in the production of high-quality metal products.