When machining parts in different fields, there are different choices for materials. Some parts may seek alternatives to aluminum for CNC machining compared to the commonly used aluminum material. After all, every metal has its advantages and disadvantages.

Below are some potential machining alternatives for aluminum, and this article highlights their similarities and differences with aluminum. You can find the CNC machining materials suitable for your custom parts through this article.

– Metal Materials:

- Steel and Stainless Steel

Steel and stainless steel are widely used materials in CNC machining. Due to its high strength, steel is often favored for high-stress applications and those that require strong welds. Steel can withstand very high temperatures, and stainless steel can be heat treated to enhance its corrosion resistance.

However, while machining steel is designed for improved machinability, aluminum is still easier to machine than machining steel. Steel is also heavier and harder than aluminum, both of which are also considered, depending on the application. If the key consideration is temperature resistance rather than weight, steel may be a good alternative to aluminum.

- Titanium

Titanium can be used as a like-for-like replacement for aluminum because its main advantage is its superior strength-to-weight ratio—one of aluminum’s main advantages. Titanium weighs similarly to aluminum but is nearly twice as strong. Like aluminum, it also has strong corrosion resistance. These advantages are reflected in titanium’s higher price point. While the material is an excellent choice for parts such as aircraft components and medical devices, its cost can be prohibitive. When lightweighting is a primary concern and, more importantly, when there is some flexibility in the manufacturing budget, machining titanium is a suitable alternative to aluminum.

- Magnesium

While the lightweight metal magnesium is not the most commonly machined material, it shares many of the advantages of common aluminum alloys. In fact, magnesium is one of the easiest metals to machine, making the process quick and efficient. One potential drawback for machine shops? Magnesium chips are extremely flammable, which is further exacerbated by water, meaning machinists must be careful when removing the debris. And magnesium’s corrosion resistance is not excellent.

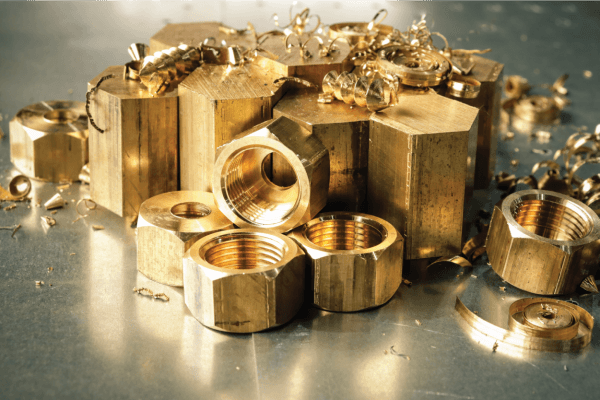

- Brass (Copper-Zinc Alloy)

Brass, a metal with a golden appearance, is a highly machinable metal that is hard and wear-resistant, and is slightly more expensive than aluminum. It is commonly found in parts such as valves and nozzles, as well as structural components, and its high machinability makes it suitable for large-volume orders.

- Pure Copper

Copper shares many of the same material properties as aluminum. However, copper’s superior electrical conductivity makes it more suitable for a variety of electrical applications. While pure copper is difficult to machine, many copper alloys have similar machining properties to popular aluminum grades.

2. Engineering Thermoplastics:

- POM (Polyoxymethylene)

CNC machining projects don’t have to be limited to metals. In fact, several engineering thermoplastics can match or exceed some of the benefits of aluminum, depending on the application. Since aluminum is often favored for its excellent machinability, one viable plastic alternative is POM, which is well suited to machining processes like aluminum. POM has a lower melting point, but is very strong as a plastic. POM is an electrical insulator, making it suitable for parts such as electronic housings, but it is also suitable for mechanical parts. However, because its insulating properties are so different from aluminum, it can only be used as a like-for-like replacement when thermal and electrical conductivity are negligible.

- PTFE (Teflon)

Like POM, PTFE (Teflon) is a highly machinable thermoplastic that is an excellent electrical insulator and has very low friction. However, unlike POM, PTFE is also resistant to high temperatures (up to 260°C), making it a viable aluminum replacement for high-temperature applications. In addition, PTFE (Teflon)’s high chemical resistance makes it a common material for machining parts in the food industry.

- PEEK (Polyetheretherketone)

Although PEEK is more difficult to machine than the previous two thermoplastics, its high strength and thermal stability (resistant to temperatures up to 260°C) make it a true like-for-like replacement for aluminum. PEEK is widely used in aerospace, automotive, medical devices, electronics, petrochemicals and other fields, and its popularity in machining parts such as valves, bearings, pumps and nozzles is a testament to its metal-like capabilities. One stumbling block is price. As a high-performance polymer, PEEK is one of the more expensive thermoplastics to machine, so it is only suitable for machining projects where more common materials such as aluminum cannot be used.

- ABS

ABS is commonly used as an injection molding material and, in recent years, as 3D printing filament. While ABS has little in common with aluminum, it is still a versatile, lightweight material for CNC machining with above-average impact strength.

| Application | Aluminum | Selection |

| General Purpose | 6061 | Mild Steel 1018 |

| Aerospace | 7075 | Stainless Steel 303 |

| Marine | 5083 | Stainless Steel 304 Stainless Steel 316 |

| Construction | 5083 | Mild Steel A36 |

| Food And Beverage | 6061 | PTFE PC |